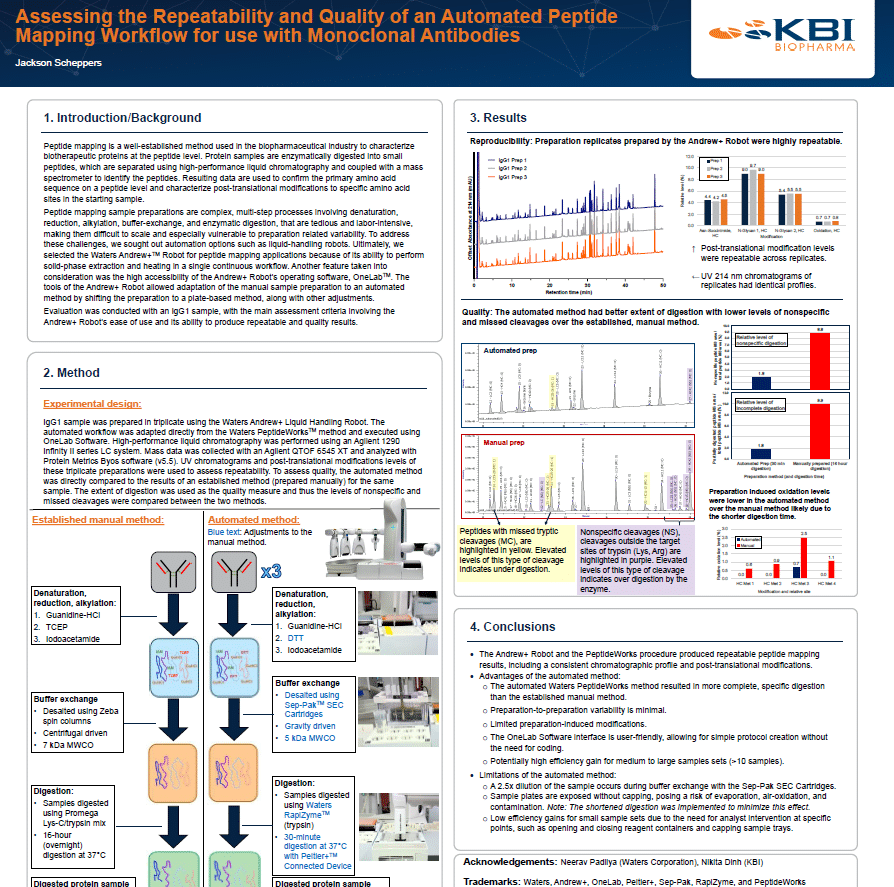

Peptide mapping is a well-established method used in the biopharmaceutical industry to characterize biotherapeutic proteins at the peptide level. Protein samples are enzymatically digested into small peptides, which are separated using high-performance liquid chromatography and coupled with a mass spectrometer to identify the peptides. Resulting data are used to confirm the primary amino acid sequence on a peptide level and characterize post-translational modifications to specific amino acid sites in the starting sample.

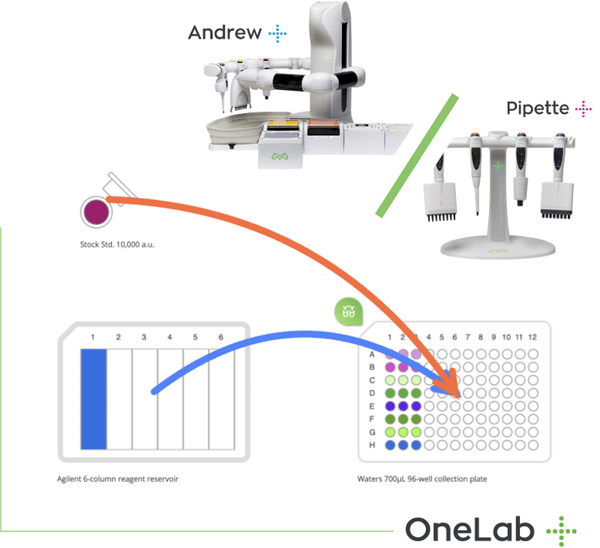

Peptide mapping sample preparations are complex, multi-step processes involving denaturation, reduction, alkylation, buffer-exchange, and enzymatic digestion, that are tedious and labor-intensive, making them difficult to scale and especially vulnerable to preparation related variability. To address these challenges, we sought out automation options such as liquid-handling robots. Ultimately, we selected the Waters Andrew+TM Robot for peptide mapping applications because of its ability to perform solid-phase extraction and heating in a single continuous workflow. Another feature taken into consideration was the high accessibility of the Andrew+ Robot’s operating software, OneLab TM. The tools of the Andrew+ Robot allowed adaptation of the manual sample preparation to an automated method by shifting the preparation to a plate-based method, along with other adjustments. Evaluation was conducted with an IgG1 sample, with the main assessment criteria involving the Andrew+ Robot’s ease of use and its ability to produce repeatable and quality results.